Name/Title

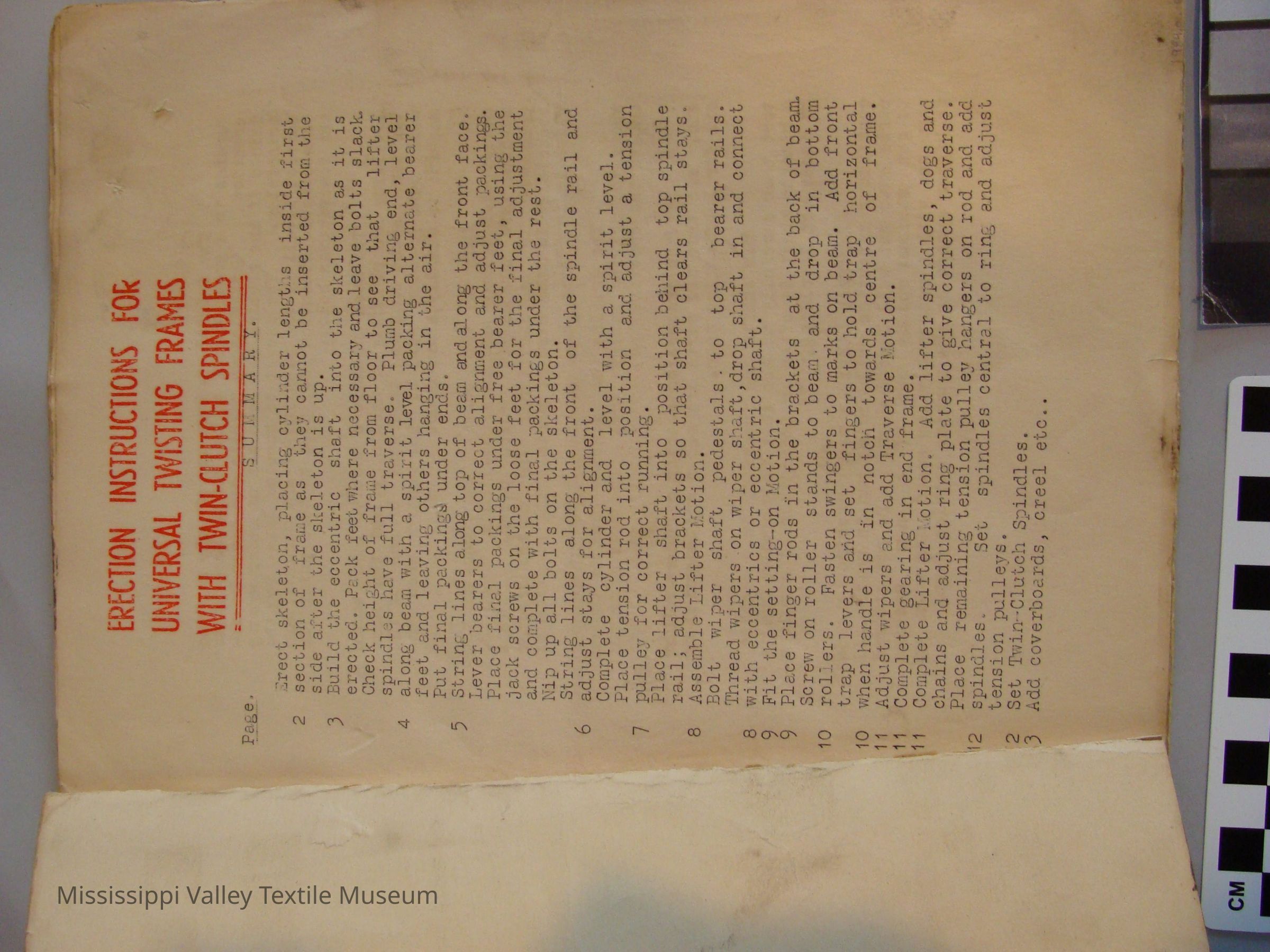

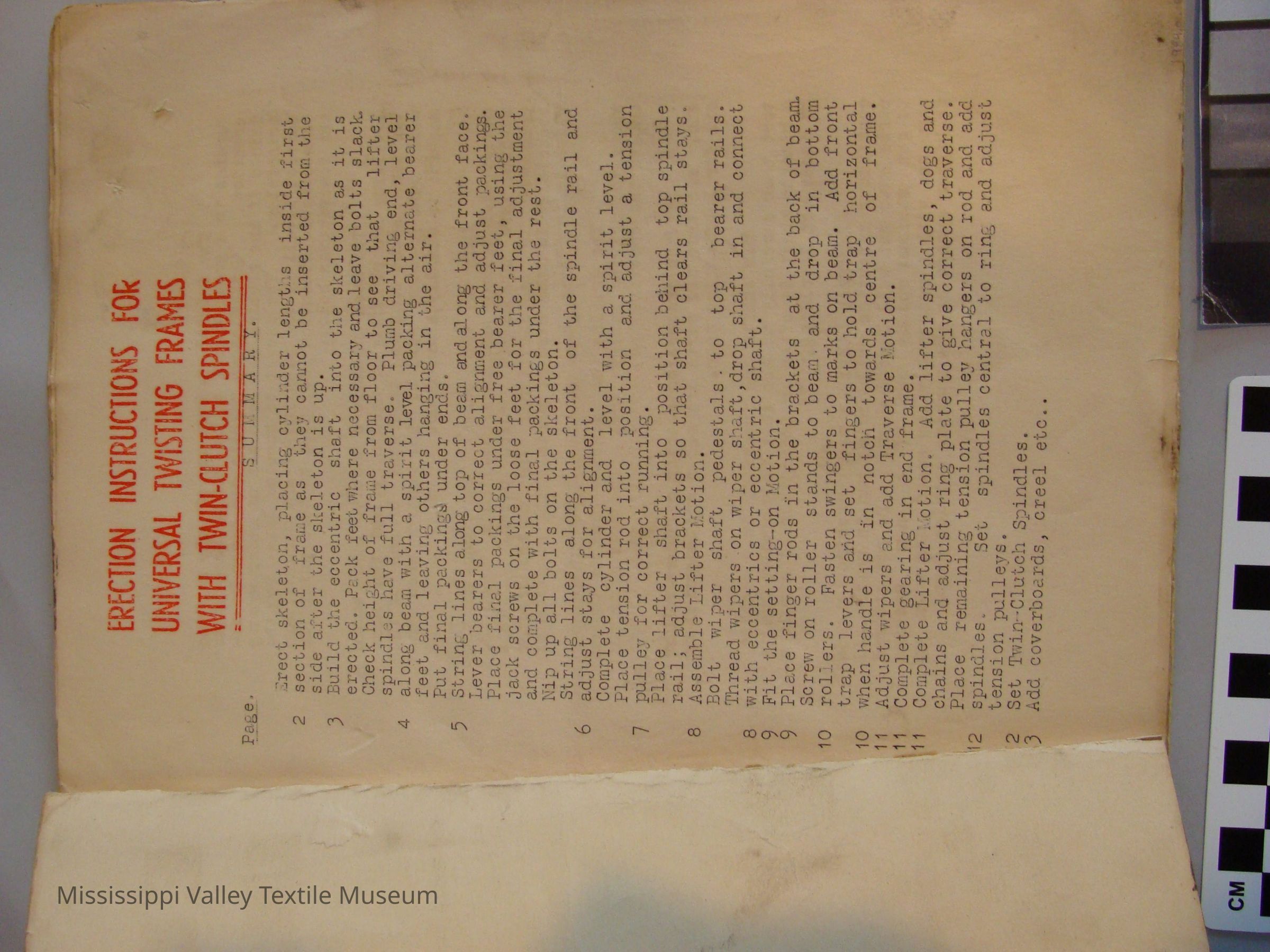

Erection Instructions for universal twisting frames with twin-clutch spindlesEntry/Object ID

1984.01.16aScope and Content

Instructions on how to assemble and adjust the universal twisting frames.

Partial transcription :

ERECTION -

INSTRUCTIONS

PRINCE -SMITH

& STELLS LTDi KEIGHLEY, ENGLAND.

ERECTION INSTRUCTIONS FOR

UNIVERSAL TWISTING FRAMES '

WITH TWIN-CLUTCH SPINDLES

Page. =

Creel skeleton, placing cylinder lengths inside first

2 section of frame as the.? cannot be inserted from the side after the skeleton is up.

3 Build the eccentric shaft into the skeleton as it is erected. Pack feet where necessary and leave bolts slack. Check height of frame from floor to see that lifter spindles have full traverse. Plumb driving end, level

4 along beam with a spirit level packing alternate bearer feet and leaving others hanging in the air.

Put final packings' under ends.

5 String lines along top of beam and along the front face. Lever bearers to correct alignment and adjust packings. Place final packings under free bearer feet, using the jack screws on the loose feet for the final adjustment and complete with final packings under the rest.

Nip up all bolts on the skeleton.

String lines along the front of the spindle rail and

6 adjust stays for alignment.

Complete cylinder and level with a spirit level.

Place tension rod into position and adjust a tension

7 pulley for correct running.

Place lifter shaft into position behind top spindle rail; adjust brackets so that shaft clears rail stays.

8 Assemble Lifter Lotion.

Bolt wiper shaft pedestals - to top bearer rails. Thread wipers on wiper shaft,drop shaft in and connect

8 with eccentrics or eccentric shaft.

9 Fit the setting-on Motion.

9 Place finger rods in the brackets at the back of beam. Screw on roller stands to beam . and drop in bottom

10 rollers. Fasten swingers to marks on beam. Add front trap levers arid set fingers to hold trap horizontal 10 when handle is in notch towards centre of frame. 11 Adjust wipers and add Traverse notion.

.11 Complete gearing in end frame.

11 Complete Lifter Motion. Add lifter spindles, dogs and chains and adjust ring plate to give correct traverse. Place remaining, tension pulley hangers on rod and add

12 spindles. Seo spindles central to ring and adjust tension pulleys.

2 Set Twin-Clutch Spindles.

3 Add coverboards, creel etc..

PRINCE SMITH & SON

BALL BEARINGS

WHEN FIXING-See that Locking Nut is placed so that it will tend to tighten during rotation.

Also see that nut is made lock the taper

sleeve as tight as possible.

LUBRICATION--The Bearings, when supplied are filled with grease. This should last for few months when a further supply should be introduced by means of grease gun

[end]

Physical Characteristics: Very dirty. Front cover and first page ripped from spine inwards on top left side. Small tears all over cover edges.Collection

Textile Industry; Machinery and AccessoriesCataloged By

Watson, MicheleLexicon

Nomenclature 4.0

Nomenclature Primary Object Term

CatalogNomenclature Sub-Class

Other DocumentsNomenclature Class

Documentary ObjectsNomenclature Category

Category 08: Communication ObjectsArchive Details

Creator

Prince-Smith & Steels Ltd.Archive Notes

Publisher: Prince-Smith & Steels Ltd.

Publication Notes: Prince-Smith & Steels Ltd. Keighley, Enland.

Place Published: Keighley, Enland.Location

Location

Container

Box 1Shelf

Shelf 47Room

Collections RoomBuilding

M.V.T.M.Category

PermanentDate

November 7, 2023Location

Container

Box 1Drawer

D37Shelf

Shelf 47, Shelf 47Room

Collections RoomBuilding

M.V.T.M.Category

PermanentMoved By

Cotter, EllenDate

June 2, 2022Category

PermanentLocation

Drawer

D38Room

Collections RoomBuilding

M.V.T.M.Category

PermanentLocation

Drawer

D37Room

Collections RoomBuilding

M.V.T.M.Category

PermanentRelationships

Related Person or Organization

Person or Organization

Adams, EarnstGeneral Notes

Note

Status: OK

Status By: Cotter, Ellen

Status Date: 2022-02-06Created By

admin@catalogit.appCreate Date

July 5, 1985Updated By

admin@catalogit.appUpdate Date

November 12, 2023