Name/Title

Card, instructions on operating WL E Gurley RD Stiffness TesterEntry/Object ID

1993.03.42bScope and Content

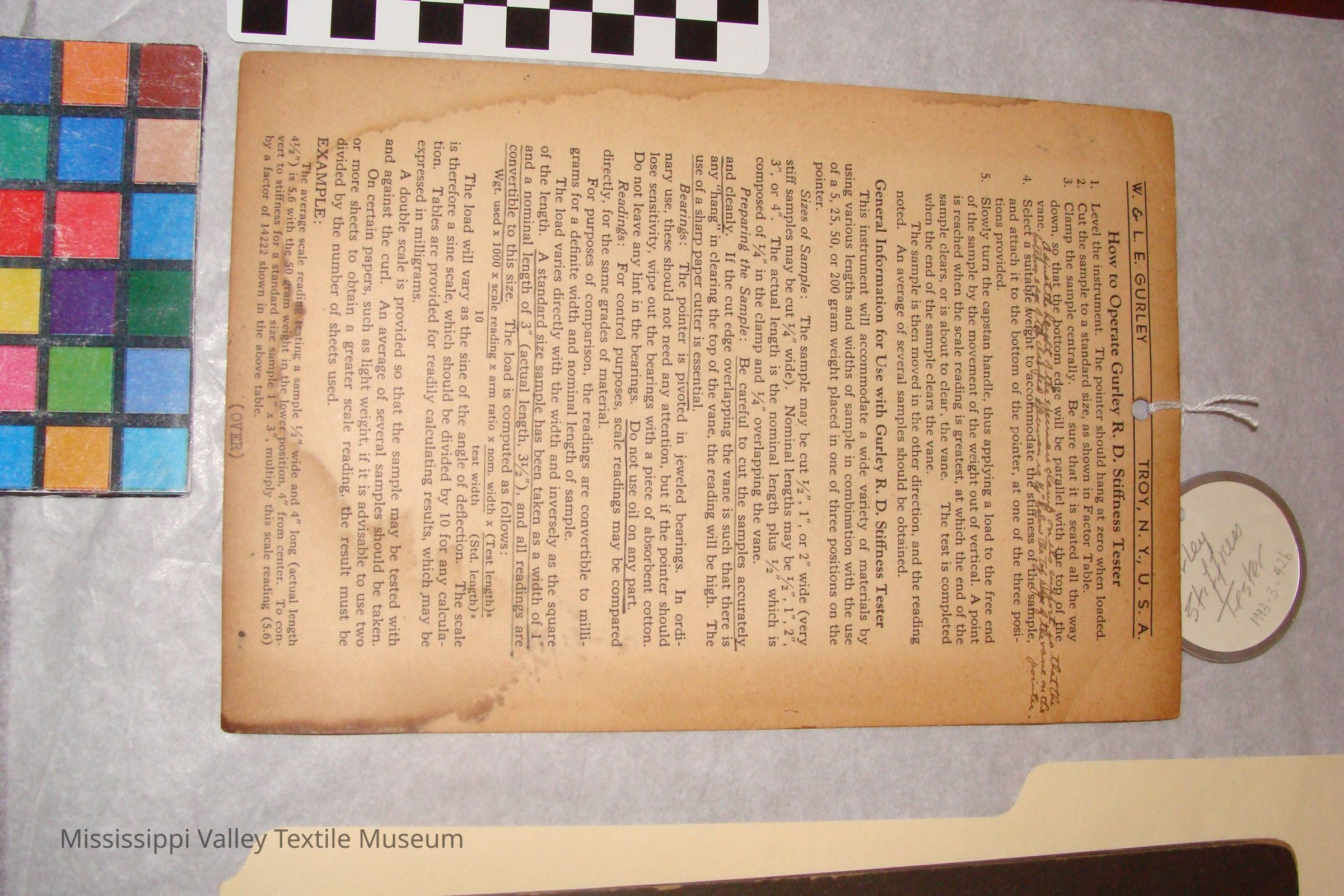

Card of info about Gurly RD Stiffness tester, one side has factors for converting scale readings to milligrams and the other side has other instructions.

Transcription:

Factors for Converting Scale Reading to milligrams, with Gurley R.D. Stiffness Tester

Multiply Average Scale Reading by Factor for Combination

Size of Sample Width ½ Inch

Size of Sample

Actual Length Inches 1 11/2 21/2 41/3 41/2

2 GRAMS WEIGHT

Distance from Center - 1' 5.56 22.2 88.9 200 356

" " " -2" 11.3 44. 178 400 711

" " " 4" 22.2 88.9 356 800 1422

25 GRAM WEIGHT:

Distance from centre - 1" 27.8 111 444 1000 1778

" " " -2" 55.6 222 889 2000 3556

" " " 4" 111 444 1778 4000 7111

50 GRAM WEIGHT:

Distance from Centre -- 2" 111 444 1778 4000 7111

" " " --4" 222 889 3356 800 14222

200 GRAM WEIGHT :

Distance from Centre -2" 444 1778 7111 16000 2844

" " " -4" 859 3556 14222 32000 56888

SIZE OF SAMPLE: Width 1 Inch

Actual Length - Inches 1 1 ½ 1 ½ 31/2 41/2

5 GRAM WEIGHT:

Distance from Centre-1" 2.78 11.1 44.4 100 178

" " " --- 2" 5.56 22.2 88.9 200 356

" " "4" 11.1 44.4 178 400 711

25 GRAM WEIGHT :

Distance from centre - 1" 13.9 55.6 222 500 889

" " " - 2" 27.8 111 444 1000 1778

" " " -4" 55.6 222 889 2000 3556

50 GRAM WEIGHT:

Distance from Centre - 2" 55.6 222 889 2000 3556

" " " -- 4" 111 444 1778 4000 7111

200 GRAM WEIGHT :

Distance from Centre - 2" 222 889 3556 8000 14222

" " " 4" 444 1778 7112 16000 28444

SIZE OF SAMPLE:

Actual Length - inches 1 12/3 2 ½ 3 ½ 4 ½

5 GRAM WEIGHT:

Distance from Centre -1" 1.39 5.56 22.2 50 88.9

" " " -2" 2.78 11.1 44.4 100 178

" " " -4" 5.56 22.2 88.9 200 356

25 GRAM WEIGHT :

Distance from Centre - 1" 6.94 27.8 111 250 444

" " " -2" 13.9 55.6 222 5000 889

" " " -4" 27.8 111 444 1000 1778

50 GRAM WEIGHT :

Distance from Centre - 2" 27.8 111 444 1000 1778

" " " -4" 55.6 222 886 2000 3556

200 GRAM WEIGHT:

Distance from Centre - 2" 111 444 1778 4000 7112

" " " - 4" 222 886 3556 8000 14222

(OVER)

-2-

W.G.L.E. GURLEY TROY, N.Y., U.S.A.

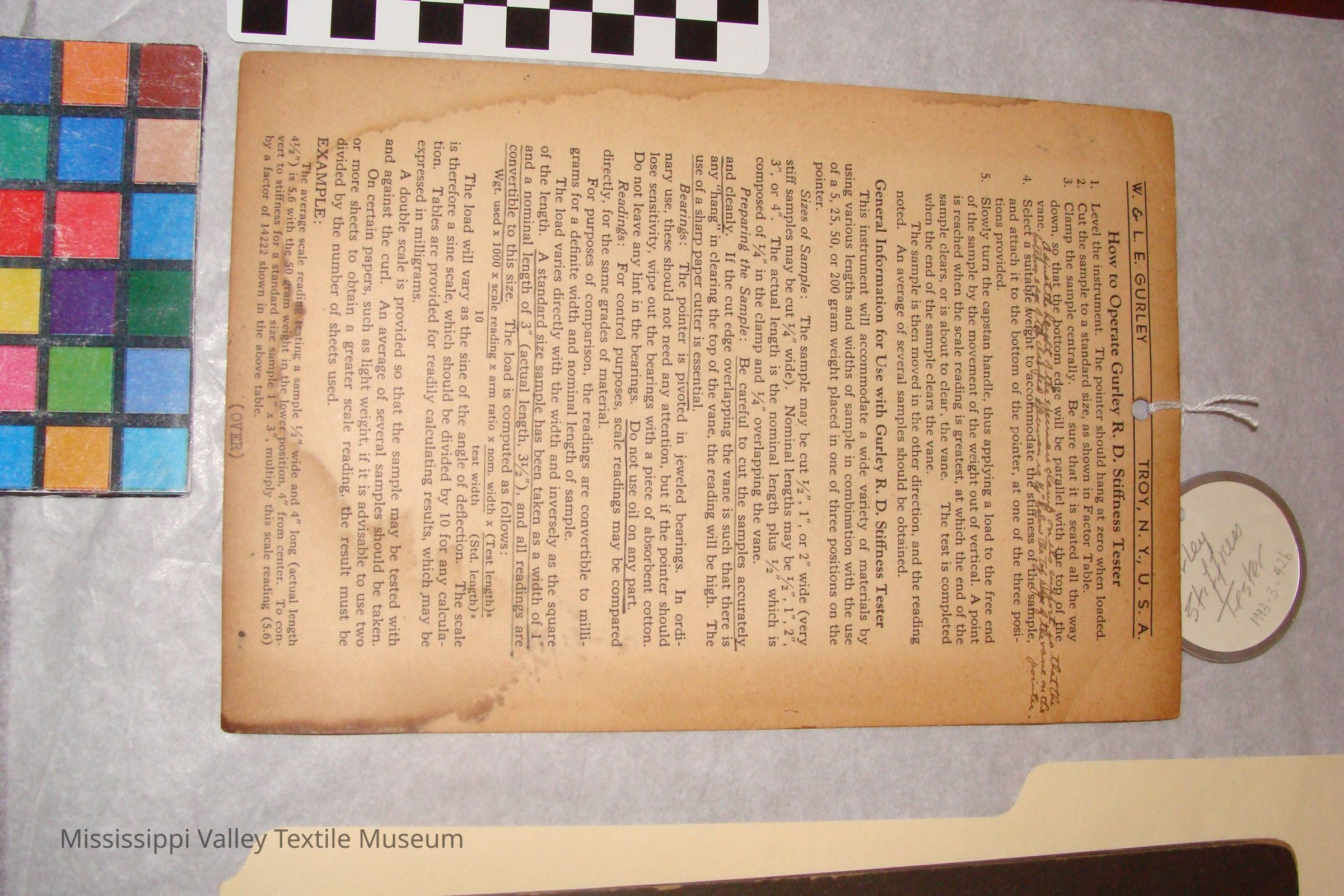

How TO Operate Gurley R.D.Stiffness Tester

1. Level the Instrument. The pointer should hang ut zero when loaded.

2. Cut the sample to a standard size, as shown in Factor Table.

3. Clamp the sample centrally, Be sure that it is seated all the way down, so that the bottom edge will be parallel with the top of the vane

[several handwritten sentences]

4. Select a suitable weight to accommodate the stiffness of the sample , and attach it to the bottom of the pointer, at one of the three positions provided.

5. Slowly turn the capstan handle , thus applying a load to the free end of the sample by the movement of the weight out of vertical. A point is reached when the scale reading is greatest, at which the end of the sample clears, or is about to clear, the vane. The test is completed when the end of the sample clears the vane. The sample is then moved in the other direction, and the reading noted. An average of several samples should be obtained.

General information for use with Gurley, R.D. Stiffness Tester

This instrument will accommodate a wide variety of materials by using various lengths and widths of sample in combination with the use of a 5,25,50 or 200 gram weight placed in one of three positions on the pointer.

Size of Sample: The sample may be cut ½", 1" or 2" wide (very stiff samples may be cut ¼" wide). Nominal lengths may be ½", 1", 2", 3" or 4". The actual length is the nominal plus ½"which is composed of ¼" in the clamp and ¼" overlapping the vane.

Preparing the sample: : Be careful to cut the samples accurately and clearly. If the cut edge overlapping the vane is such that there is any "hang" in clearing the top of the vane, the reading will be high. The use of a sharp paper cutter is essential.

Bearings: The pointer is pivoted in jeweled bearing. In ordinary use, these should not need any attention, but if the pointer should lose sensitivity, wipe out the bearings with a piece of absorbent cotton. Do not leave any lint in the bearings. Do not use oil on any part.

Readings: For control purposes, scale readings may be compared directly. For the same grades of material.

For purposes of comparison, the readings are convertible to milligrams for the definite width and nominal length of sample.

The load varies directly with the width and inversely as the square of the length., A standard size sample has been taken as a width of 1" and a normal length of 3" (actual length , 3 1/2). And all readings are convertible to the size. The load is computed as follows :

Wgt used x 1000 x scale reading / 10 x arm ratio x norm weidth/test width x (Test lengths)/(std. length)

The load will vary as the sine of the angle of deflection. The scale is therefore a sine scale , which should be divided by 10 for any calculation., Tables are provided for readily calculating results , which may be expressed in milligrams.

A double scale is provided so that the sample may be tested with and against the url. An average of several samples should be taken. On certain papers such as light weight , if it is advisable to use two or more sheets to obtain a greater scale reading. The result must be divided by the number of sheets used.

Example :

The average scale reading testing a sample ½ " wide and 4" long (actual length 4 ½") is 5.6 with the 50 gram weight in the lower position 4" from centre. To convert to stiffness for a standard size sample 1" x 3, multiply this scale reading (5.6) by a factor of 14222 shown in the above table (OVER)

[end]Collection

Textile IndustryCataloged By

Whit, ElizabethLocation

Location

Container

Archive Box 1Shelf

1Cabinet

Archive CupboardRoom

Collections RoomBuilding

M.V.T.M.Category

PermanentDate

November 7, 2023Location

Container

Archive Box 1Shelf

Shelf 1, Shelf 1Room

Collections RoomBuilding

M.V.T.M.Category

PermanentMoved By

Whit, ElizabethDate

August 7, 2016General Notes

Note

Status: OK

Status By: MacMillan, Lindsay

Status Date: 2020-11-30Created By

admin@catalogit.appCreate Date

August 7, 2016Updated By

admin@catalogit.appUpdate Date

November 12, 2023